The important components on the machine from developed countries :Japan main hydraulic pump,Italy main valve ,Italy swing motor and travelling motor .

1. The important components on the machine from developed countries :Japan main hydraulic pump,Italy main valve ,Italy swing motor and travelling motor .

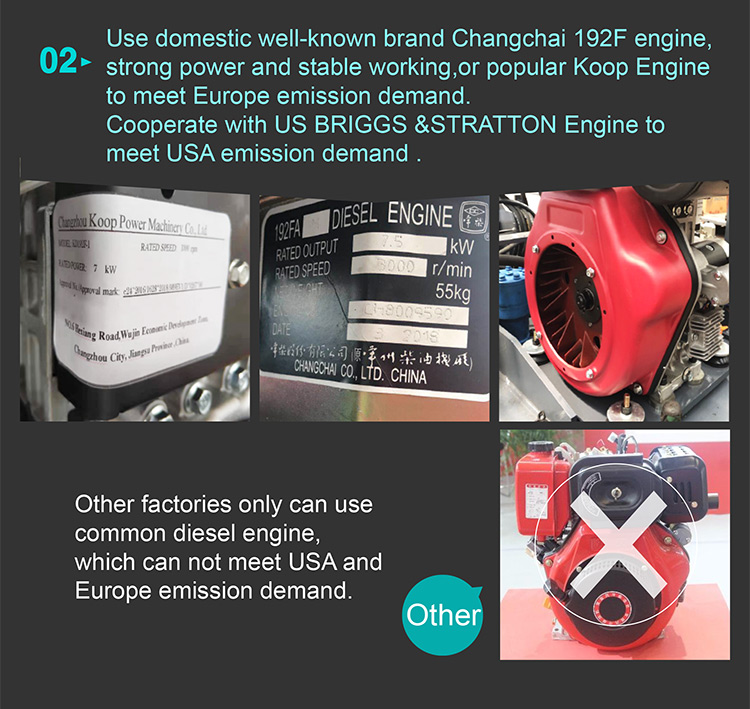

2. Use domestic well-known brand Changchai 192F engine, strong power and stable working,or popular Koop Engine to meet Europe emission demand. Cooperate with US BRIGGS &STRATTON Engine to meet USA emission demand .

Other factories only can use common diesel engine,which can not meet USA and Europe emission demand .

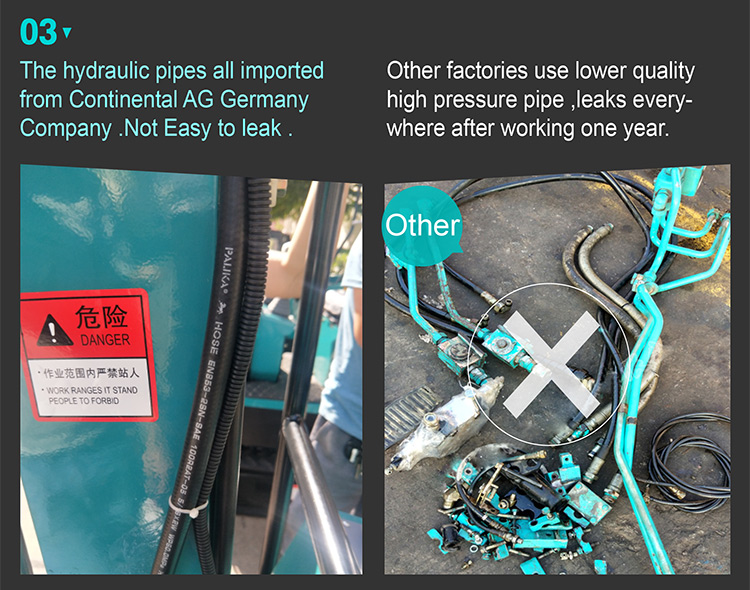

3. The hydraulic pipes all imported from Continental AG Germany Company .Not Easy to leak .

Other factories use lower quality high pressure pipe ,leaks everywhere after working one year.

4.100 kg counterweight is added to the rear of the machine which making the machine work more stable and powerful

5. The structural parts of the machine are processed by Japan komatsu Engine supporting manufacturers, and the whole vehicle is shot blasted, pickled, phosphated, and sprayed, which increases the adhesion of the paint molecules, and is more durable, non-bleaching and smoother.

Other manufacturers do not have these procedures, only simply polish and spray paint, which is easy to get rusty

6. The machine adds a pressure reducing valve device, which makes it easier to start when the machine starts.

No pressure reducing valve ,hard to start machine .

7. The dozer blade length can be adjusted according to the scope of work: 84cm-105cm,the dozer blade working height can be adjusted from -15cm to 15cm highest .

Other factories can only do fix length at 1000mm

8. The crawler can be stretched from minimum 830 to maximum 1000mm which and can pass through more narrow places .

Other factories wheelbase can be only designed fix at 910mm

9:The boom can be deflected by 60 degrees turning left and right, making the job more flexible.

Other factories can only design fix boom or just turning by 30 degrees .

|

Model |

HT-10 |

|

Weight |

1000kg |

|

Digging bucket capacity |

0.025cbm/120kg |

|

Bucket width |

380mm |

|

Engine |

Koop Engine 192F

|

|

Optional Engine |

Briggs & Stratton Engine Yanmar Engine |

|

Bore stroke |

Single cylinder, fan cool |

|

Rated power |

7kw/3000r/min

|

|

Main pump |

G5-6

|

|

Displacement |

6.8ml/r |

|

Swing motor |

SANYANG (BMRS-250)

|

|

Traveling motor |

SANYANG (BMT-245)

|

|

Travel speed |

1. 5km/h |

|

Main Demensions |

|

|

Overall dimension( LxWxH) |

2775 X 930 x 2219 mm |

|

Wheelbase |

910 mm

|

|

Total length of track |

1230mm |

|

Platform ground clearance |

380mm |

|

Platform back turming radius |

784 mm |

|

Chassis width |

896 mm |

|

Track width |

180 mm |

|

Chassis ground clearance |

132 mm |

|

Track height |

320 mm |

|

Operating Range |

|

|

Max. Digging depth |

1650 mm |

|

Max. Vertical digging depth |

1375 mm |

|

Max. Digging height |

2610 mm |

|

Max. Dumping height |

1850 mm |

|

Max. Digging radius on ground |

2850 mm |

|

Min. Rotation radius |

1330 mm |

|

Max. Upgrade height of bulldozer blade |

345mm |

|

Max. Digging depth of bulldozer blade |

255 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Please fill out the form below according to your needs and a sales manager will contact you within one business day.